External wall insulation (EWI) dramatically improves a building’s thermal efficiency and protects its exterior from the elements. By wrapping your property in a layer of insulation and adding a weather‑resistant finish, you can reduce heat loss, cut energy bills and improve comfort year‑round. However, EWI isn’t simply a case of sticking insulation boards to brickwork – it’s a significant construction project that needs careful planning. Before starting, homeowners must understand whether permission is required, how to prepare the property, and why a certified installer makes all the difference. This External Wall Insulation Checklist 2026: What to Know will guide you through the key considerations for a successful project.

Content Page

- Why Plan Your External Wall Insulation?

- Do You Need Planning Permission and Building Control Approval?

- External Wall Insulation Checklist 2026: What to Know

- Choosing a Certified EWI Installer

- What Documents and Permissions You Need

Why Plan Your External Wall Insulation?

Installing EWI is one of the most effective ways to upgrade a property’s energy performance. The extra thermal layer reduces heat lost through walls and can lower heating bills. It also helps to eliminate cold bridges and condensation, protecting against mould and structural damage. Because it alters the fabric of your home, EWI is subject to planning rules and building regulations. Failing to follow the correct procedures can lead to legal complications or poor performance. A proper plan ensures that you:

- Meet legal requirements: different areas and property types have different rules, especially listed buildings or those in conservation areas. Understanding these before you start avoids costly mistakes.

- Prepare the building: addressing structural defects, damp and existing finishes ensures the insulation adheres properly and performs well.

- Choose qualified installers: certified companies follow recognised standards and provide warranties.

Do You Need Planning Permission and Building Control Approval?

Planning rules differ across the UK, but there are some general principles to guide you:

Planning Permission

For most ordinary homes, adding insulation that does not change the exterior’s appearance is considered permitted development and doesn’t require planning permission. However, you will need permission if:

- Your property is listed or in a conservation area – local authorities protect historic or architecturally significant buildings. Any significant change, including EWI, requires listed building consent.

- You live in an Area of Outstanding Natural Beauty, National Park or an area covered by an Article 4 Direction, where even minor changes need permission.

- The work will materially change the external appearance, for example by increasing the wall thickness or altering finishes. The Planning Portal advises that cladding may be allowed if the materials are similar to the existing house, but other finishes (e.g. coloured render) may require consent.

If in doubt, contact your local planning authority to confirm whether your project requires consent. Councils often recommend applying for a Lawful Development Certificate when you believe the work is permitted; this provides written confirmation that no permission is necessary.

Building Regulations

Even if planning permission isn’t required, building regulations usually apply. The Building Regulations treat walls as thermal elements and require them to be upgraded when 25 per cent or more of the external surface is re‑rendered or clad. You’ll need to ensure the insulation thickness and finishes meet the standards in Approved Document L, which covers energy conservation and limits heat gains and losses. Building control approval is about more than insulation thickness – it also checks structural stability, weather resistance and fire safety. Guidance about filling cavities or placing insulation at least 150 mm below the damp‑proof course relates specifically to cavity wall retrofits rather than external wall insulation. Your installer will ensure any cavity work complies with the relevant regulations while designing the EWI system.

External Wall Insulation Checklist 2026: What to Know

Proper preparation is essential for both performance and longevity. A detailed survey of your property should be undertaken before installation begins. Industry guidance suggests using a checklist that covers property details, existing finishes, structural defects, damp and condensation issues, and service penetrations.

Structural Checks

Inspect the existing walls for cracks, loose masonry and structural movement. Minor hairline cracks may be cosmetic, but larger or stepped cracks could indicate underlying movement and should be assessed by a structural engineer. Loose or hollow render must be removed and repaired so that the insulation has a secure base. Older properties often have weaker mortar joints or coatings that need stripping before insulation can be applied.

Moisture and Damp

Identify and treat any damp issues before installing EWI. Trapping moisture behind insulation can lead to mould, rot and system failure. Visual signs include dark patches, peeling paint, mould growth or salt deposits. Use a damp meter to check moisture levels – anything above 20 per cent requires investigation and remediation. Determine whether the problem is rising damp, penetrating damp or condensation and address it accordingly:

- Rising damp: look for tide marks near the base of walls. Ensure there is a working damp-proof course and repair or install one if necessary.

- Penetrating damp: fix leaking gutters, pipes and porous masonry that let water in.

- Condensation: improve ventilation to reduce indoor humidity and consider vapour‑permeable insulation.

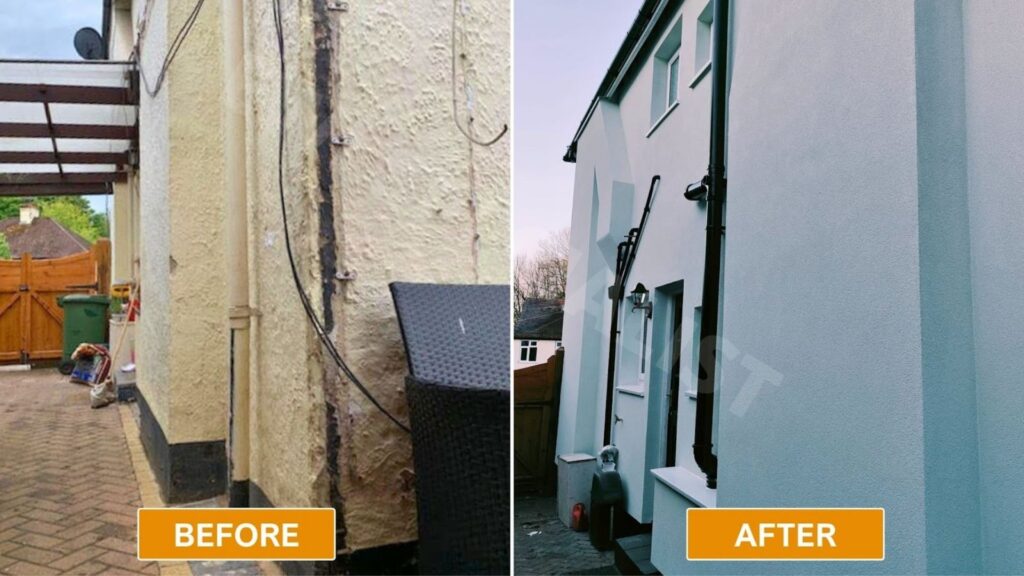

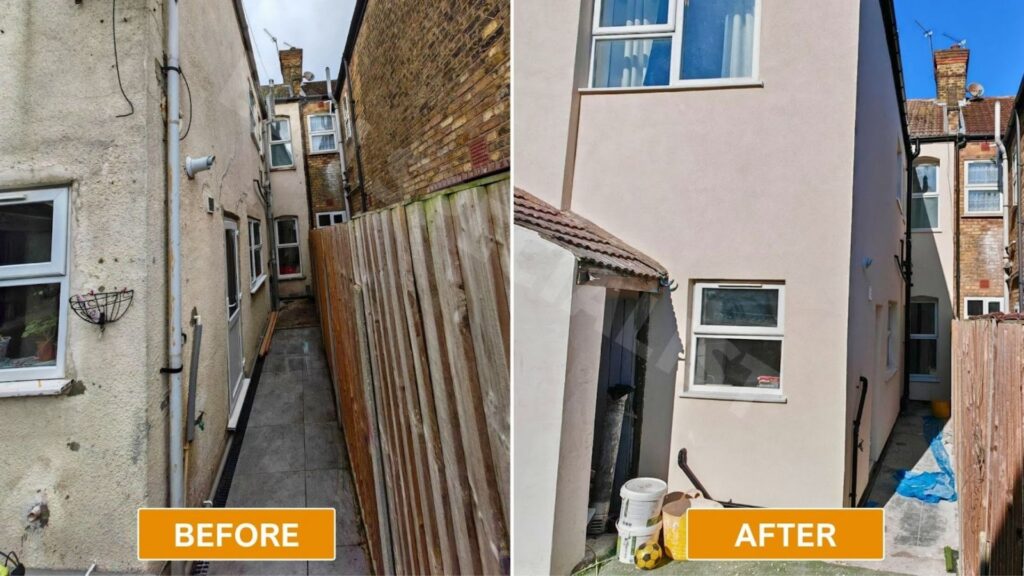

Surface Preparation

The substrate must be sound, clean and level. Remove loose paint, flaking render and moss or mould. Many system manufacturers require a primer to be applied before the adhesive; skipping this step can weaken the bond. Insulation boards should be installed in a staggered pattern like brickwork to avoid continuous vertical joints. After fixing, lightly sand or rub down the boards to remove uneven areas. Fill gaps between boards with appropriate insulation material or expanding foam, not basecoat, to eliminate thermal bridges.

Choosing a Certified EWI Installer

Selecting a competent installer is crucial. Poor workmanship leads to cold spots, damp patches and premature failure of the insulation system. Here’s what to look for:

TrustMark Registration

TrustMark is the UK government‑endorsed quality scheme for tradespeople. Businesses accredited by TrustMark are vetted for technical competence, trading practices and customer service. TrustMark‑registered EWI installers follow the PAS 2035/2030 standards, undergo regular checks by certification bodies and can access government funding schemes. They must provide insurance‑backed guarantees and offer clear complaints procedures, giving homeowners added protection.

PAS 2030 Certification

PAS 2030 is a UK standard that outlines requirements for installing energy‑efficiency measures. To be certified, installers must have appropriate qualifications, hold valid insurance, follow a documented quality management system and submit to regular audits. Only PAS 2030‑certified installers can carry out work under schemes such as the Energy Company Obligation (ECO), and the certification demonstrates professionalism and quality assurance.

These accreditations show that the installer meets industry standards and can issue long‑term warranties.

What Documents and Permissions You Need

Before work begins, assemble the necessary documentation:

- Property survey and technical specification: your installer should provide a detailed design showing the insulation thickness, fixings, render finish and detailing around openings. This document ensures everyone understands the agreed system and finish. The Insulated Render and Cladding Association checklist includes property details, wall build‑ups, existing finishes, structural defects, damp, movement joints, heating systems, ventilation, and abutments to roofs and adjacent structures.

- Planning permission: if required, obtain planning consent or a lawful development certificate. The Leicester City Council advises that EWI usually needs permission because materials must be of a similar appearance to the existing house. Conservation areas and listed buildings always require consent.

- Building control approval: submit a building regulations application if you are re‑cladding or re‑rendering more than 25 per cent of an external wall. Your installer or designer will calculate the required U‑value and provide details to satisfy Approved Document L.

- Party wall agreement: if the property is semi‑detached or terraced and the work affects a shared wall, you may need a party wall notice and agreement with your neighbour.

- Funding paperwork: if you are applying for grants (e.g., ECO4 or Great British Insulation Scheme), ensure your installer is registered and gather any required documentation.

This External Wall Insulation Checklist 2026: What to Know guides you through the key considerations to ensure your EWI project meets regulations and delivers lasting benefits. External wall insulation can transform your home’s energy efficiency, appearance and comfort. By following this checklist, you’ll avoid the pitfalls that lead to delays, extra costs or poor performance.

Always check whether planning permission is needed, secure building control approval for substantial works, and prepare your property by addressing structural issues, damp and surface preparation. Choosing a TrustMark‑registered and PAS 2030‑certified installer ensures that your EWI system is designed and fitted to the highest standards.

Ready to improve your home’s efficiency? If you’d like help navigating planning rules or want a detailed survey, our EWI Specialist team is here to assist.

Use our cost calculator to estimate your project or contact us directly to discuss your external wall insulation options and ensure your installation meets all the necessary regulations and standards.